Our Services

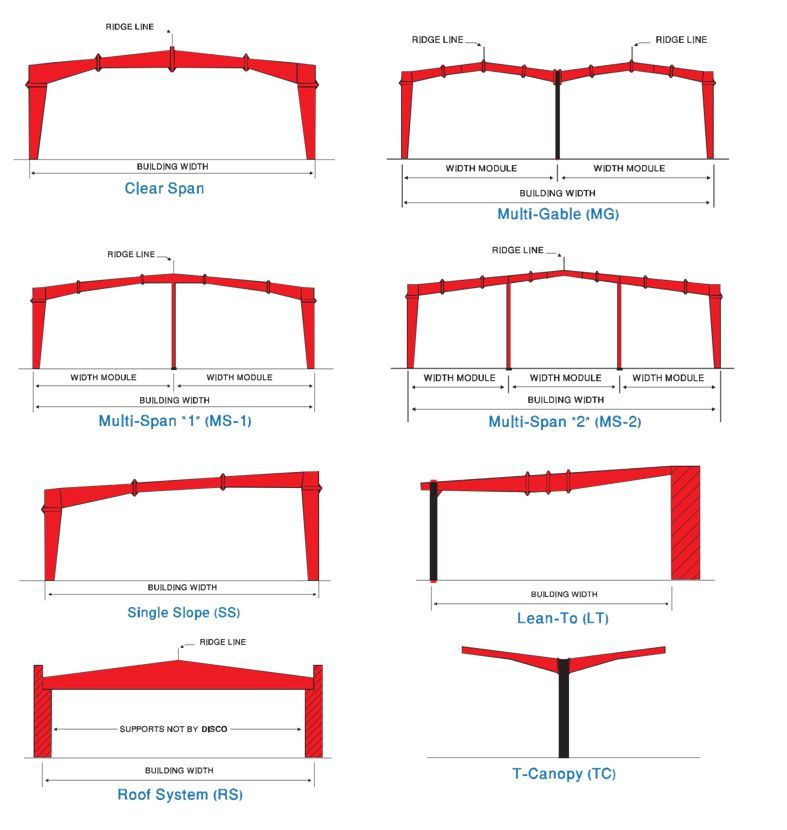

Standard Frame Types

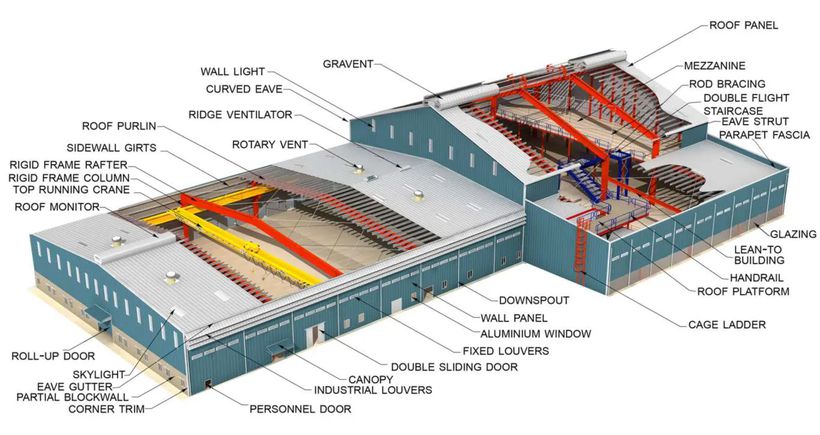

Pre-engineered buildings are defined by the following geometrical parameters: Building width, Length, Eave height, Roof slope, Sidewall bay spacing, end wall bay spacing and main frame module space. Also design loads are the basic parameter. Building Length and width are defined by the distance between steel lines. Extreme surface edges of girts and purlins are treated as steel line. Sum of side wall bay spaces will be equal to the building length. Eave height is the distance from Finished floor level to inter section point of roof and sidewall steel line.

Roof Slope is defined as the ratio between vertical distance and horizontal distance of the roof surface. Standard roof slopes are 0.5:10 and 1.0:10 To describe the side wall bay spacing, main frame column spacing to be referred start from back end wall steel line to right end wall steel line. Same way back end wall and front end wall bay spacing to be given from left side wall steel line to right side wall steel line.

We believe in building not just structures, but opportunities for progress and prosperity.

FAQ

What are Pre-engineered Buildings (PEBs)?

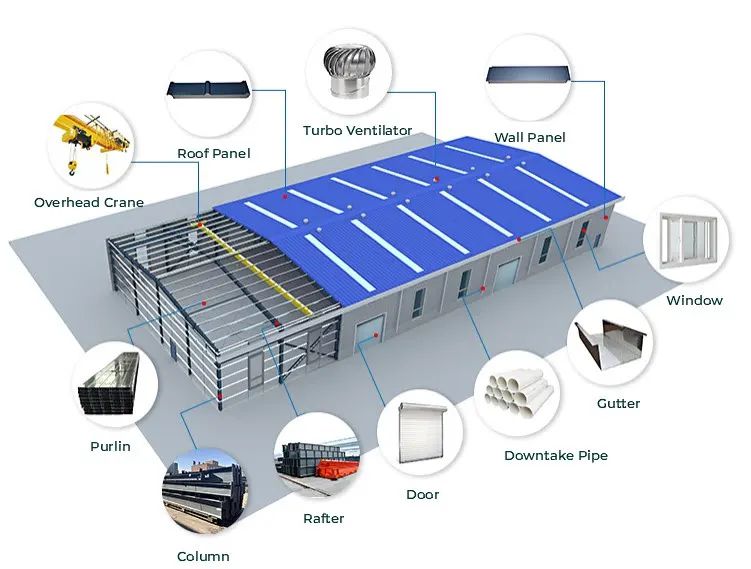

Pre-engineered buildings are structures built using pre-designed and pre-fabricated components that are manufactured off-site and assembled on-site. These components are engineered to fit together seamlessly, providing efficient construction and cost-effective solutions for various building needs.

What types of buildings can be constructed using PEB solutions?

PEB solutions can be used for a wide range of building types including warehouses, industrial facilities, commercial buildings, workshops, aircraft hangars, sports complexes, agricultural buildings, and more.

What are the advantages of opting for PEB solutions?

Some key advantages of PEB solutions include faster construction time, cost-effectiveness, flexibility in design, sustainability, and durability. Additionally, PEBs offer excellent strength-to-weight ratio and can be easily customized to meet specific project requirements.

How long does it take to construct a PEB?

The construction time for a PEB depends on various factors such as the size and complexity of the building, site conditions, and weather. However, PEBs are known for their shorter construction timelines compared to conventional buildings, with some projects being completed in significantly less time.

What is the cost comparison between PEBs and traditional construction methods?

In general, PEB solutions offer cost advantages over traditional construction methods due to factors such as reduced material waste, faster construction time, and lower labor costs. However, the cost savings can vary depending on the specific project requirements and local market conditions.

How does the design and engineering process work for PEB projects?

Our team of experienced engineers and designers collaborate closely with clients to develop customized PEB solutions. The process typically involves initial consultations, conceptual design, detailed engineering, fabrication of components, and on-site assembly. We use advanced technology and software to ensure efficient and accurate design and engineering.

How can I get started with a PEB project for my business?

To get started with a PEB project, simply reach out to our team with your requirements and project details. We’ll work with you every step of the way, from initial consultation to project completion, to deliver innovative PEB solutions that meet your needs and exceed your expectations.

Email Us – info@structurease.com

Call Us – +91 9929 233 888